COMISSIONED HIS OWN FIGURE

FERPRAD offer to his costumers the possibility of create figures in exclusive by commission in limited and numbered edition to the costumer election. His creation process is absolutely the same used for the catalogue figures. From the same time what is ordered the commission a careful process of fabrication begin.

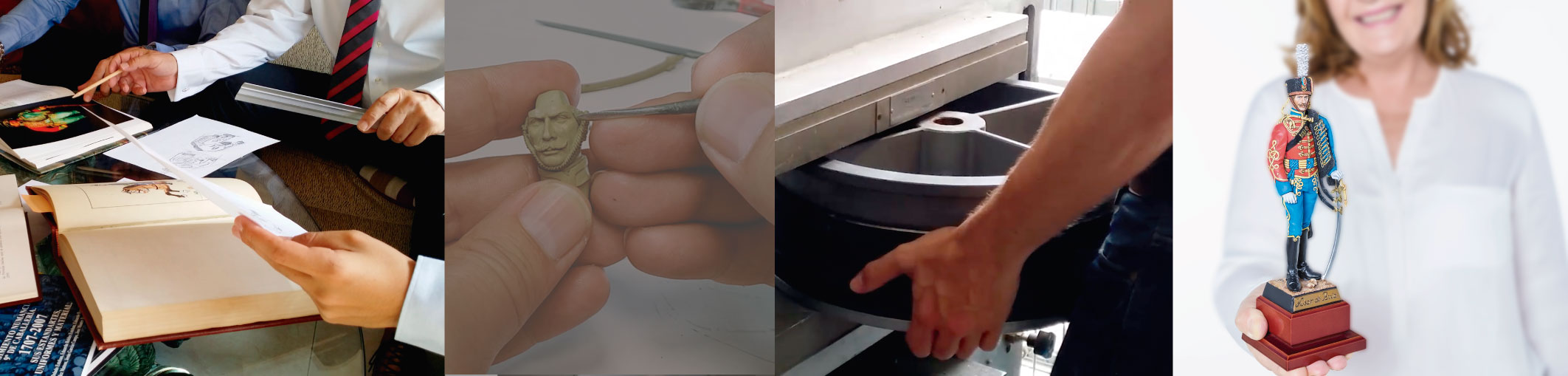

After the contact whit the costumer, FERPRAD begin a deep historical research in relation whit the uniformity and details of this figure. From this previous documentation we depart a serious research for determinate the exactitude the figure what we pretend create.

Compiled all the information, our designers create a sketch in the way how we try to mould it. We make different sketches in order to define perfectly the details and shapes of the figure whit different points of views and perspectives.

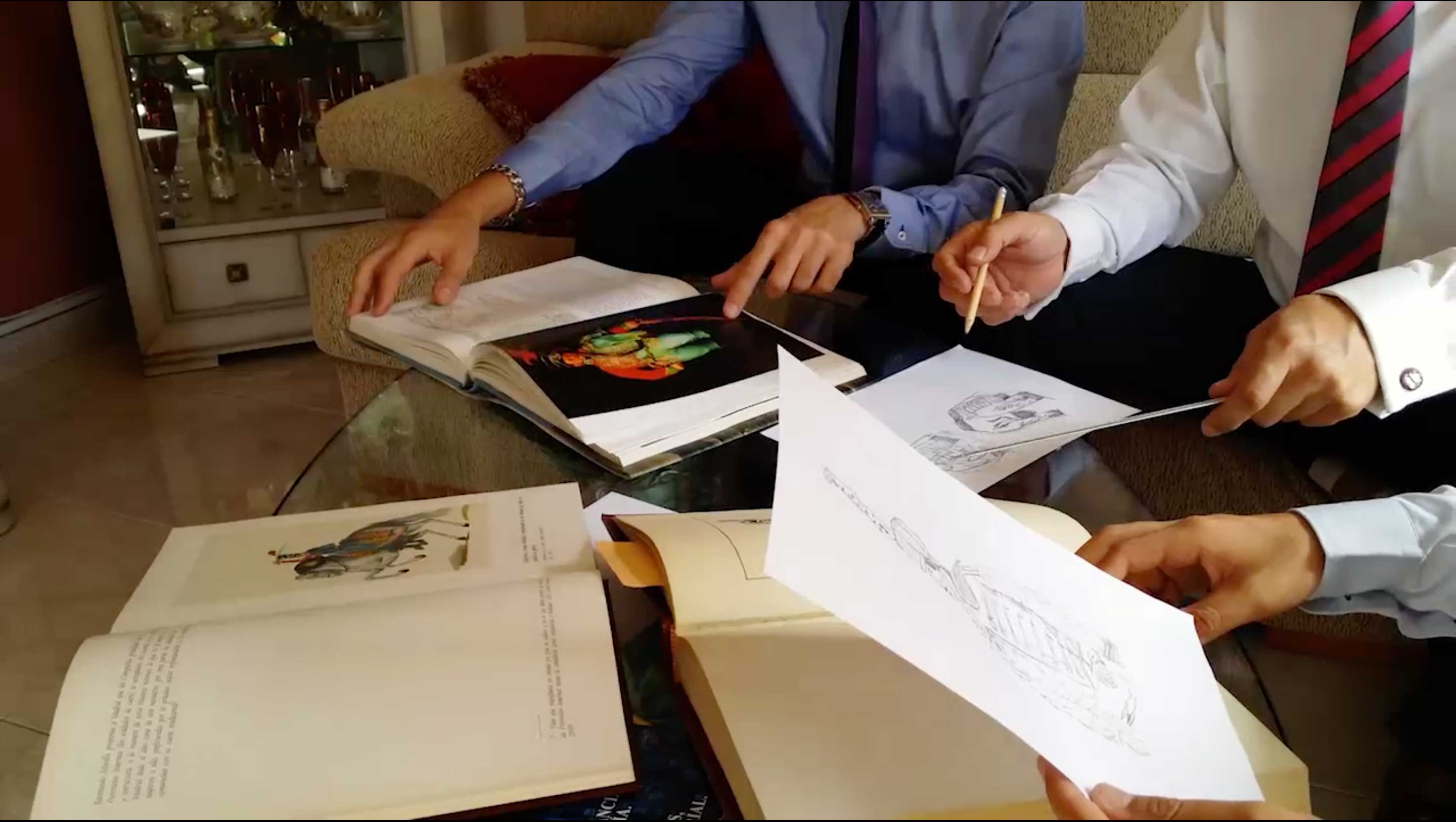

When the costumer give his approbation to the presented project begin a slow and detailed artisanal work sculpting the different pieces of the figure, from 15 to 20, with a putty mass of two exclusives components of FERPRAD

When this pieces are considered how finished they are introduced in a mould, named “pie of silicon”, in the way what they are immersed in two layers of this silicon.

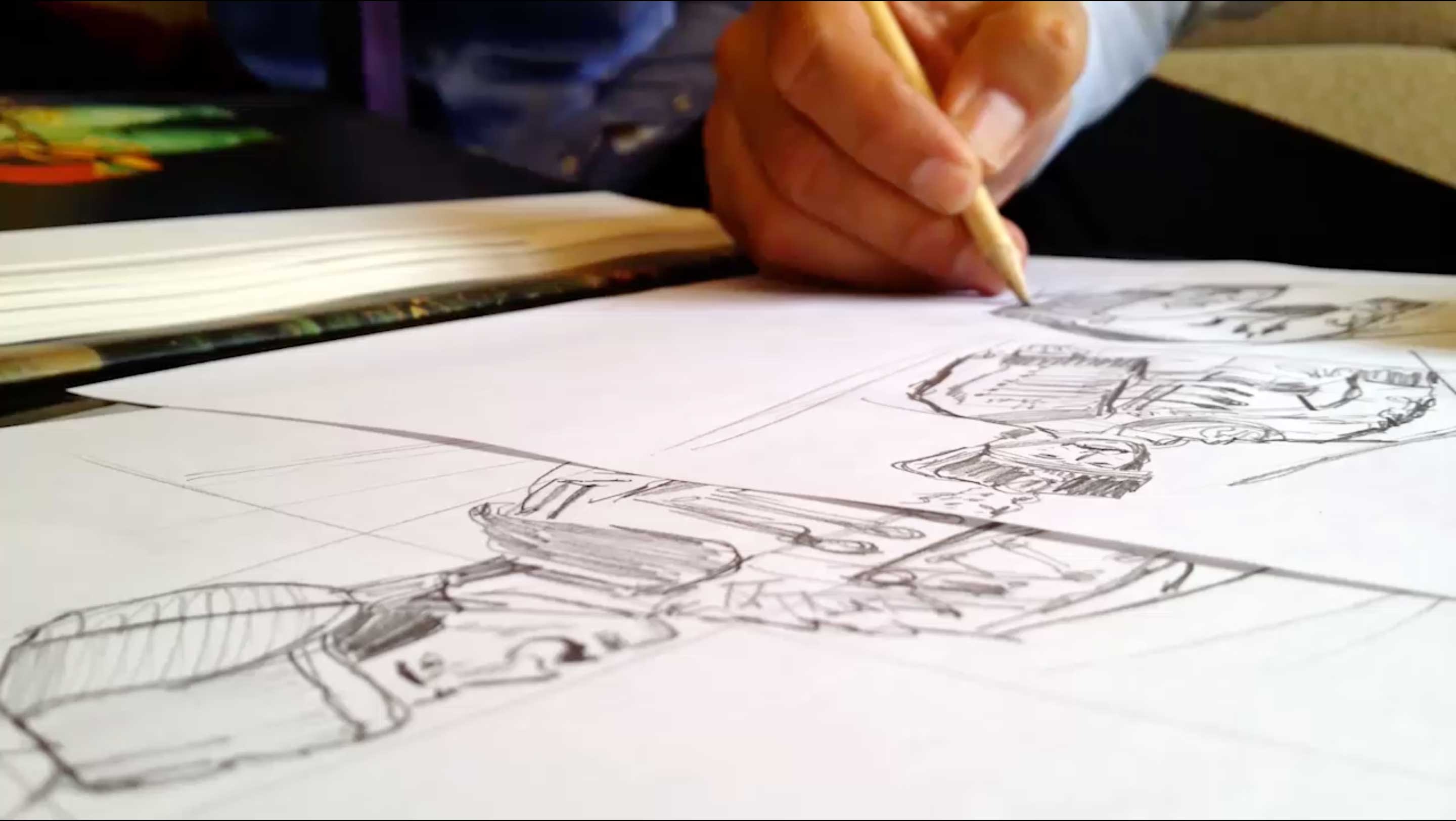

In time when they are together this two layers of silicon are placed in the oven tray for begin a vulcanized process a temperature and pressure exacts and controlled.

After the necessary time the tray is extracted for the oven and the “pie of silicon” is opened, in this moment is confirmed if is absolutely accurate the vacuums of our piece. This is the original mould, our masterpiece.

The next in this mould is make it a various channels to the vacuums in the pie of the pieces where will roam the alloy what go to dump in the next moment.

Finished the channels, we will back to close this “silicon pies” what form our mould and introduce this one in the centrifugal machine.

Is now, already in the centrifugal machine, when we dump our metal alloy, what flowing by this channels go refilling at all our pieces.

Finished the centrifugal and dry time, we separate our “silicon pies” and we see what our piece perfectly molded appears.

Retaking the artisanal process, by hand and too carefully we begin the cleaning process of our pieces, polishing any metallic rough what we can find.

With all pieces ready is begin the painting process by our specialists, what step to step them go joining all pieces to shaping the figure.

Our painters supported by a specific documentation go profiling anyone color to shape the uniformity of our figure.

A wide palette of acrylic colors gives the different tonalities. Many of these colors are exclusive mixtures made by our artists.

The use of accurate malt brushes and in particular the acknowledge mastership of our artists; make possible reproduce the more little details of any figure.

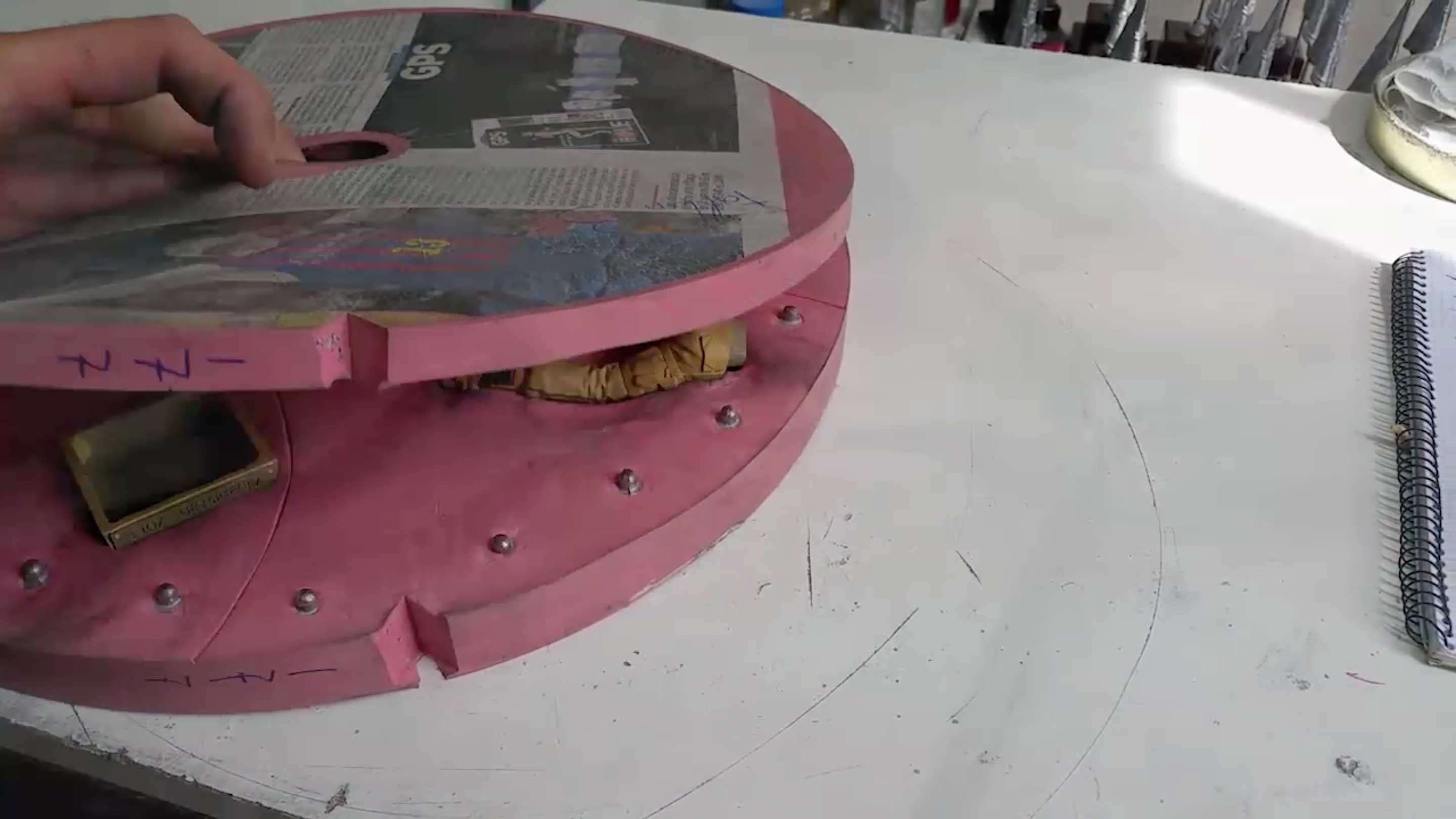

Our figure is now finish and we can let dry the paint without hurry.

How is possible see, the contrast of the details is absolutely up to a formidable level. The richest of tones facilitate to difference anyone of the wrinkles and shadows of the sculpture.

Our figure can now take is ultimate place and let in show in the way of only a piece of art deserves.

ESTAMOS A SU DISPOSICIÓN PARA INCLUIR CUALQUIER DETALLE QUE NOS SOLICITE